搜索此博客

Fei Yue Paper is Chinese professional sublimation transfer paper manufacturer, and our company is specialized in manufacturing sublimation transfer paper, sublimation dye ink, heat transfer machine for textile digital printing, If you are interested in our product, pls contact us freely. Whatsapp/Wechat:008618252072197 Email:sales@feiyuepaper.com Company website: www.skyimagepaper.com Company Name: Fei Yue Paper Industrial Co.,LTD

博文

目前显示的是 九月, 2016的博文

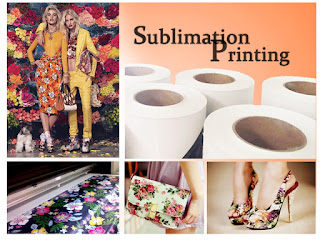

Dye Sublimation printing technology leading fashion, fitness, sportswear trend

- 获取链接

- 电子邮件

- 其他应用

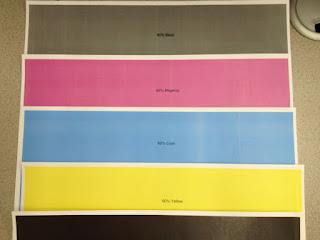

What is Banding in sublimation printing and how to avoid it?

- 获取链接

- 电子邮件

- 其他应用

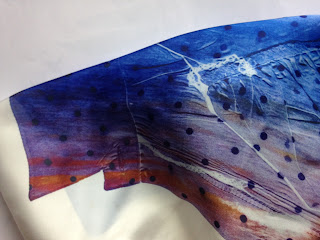

How to solve sublimation patches white line during printing?

- 获取链接

- 电子邮件

- 其他应用

Dye-sublimation printing benefits to print vibrant fabric graphics.

- 获取链接

- 电子邮件

- 其他应用

A further understanding about dye sublimation printing technology

- 获取链接

- 电子邮件

- 其他应用

Sublimation transfer paper using technology---sublimation paper printing

- 获取链接

- 电子邮件

- 其他应用

Sublimation transfer paper using technology---Transfer paper storage

- 获取链接

- 电子邮件

- 其他应用

Why our inkjet printer print head clogging and how to solve it?

- 获取链接

- 电子邮件

- 其他应用

Does every sublimation printing customers know how to manufacture sublimation paper?

- 获取链接

- 电子邮件

- 其他应用

What kind of sublimation ink you use for your Epson inkjet printer?

- 获取链接

- 电子邮件

- 其他应用

Some famous brands of sublimation printers for nowadays digital printing world

- 获取链接

- 电子邮件

- 其他应用

How to save sublimation ink during sublimation inkjet printing?

- 获取链接

- 电子邮件

- 其他应用