搜索此博客

Fei Yue Paper is Chinese professional sublimation transfer paper manufacturer, and our company is specialized in manufacturing sublimation transfer paper, sublimation dye ink, heat transfer machine for textile digital printing, If you are interested in our product, pls contact us freely. Whatsapp/Wechat:008618252072197 Email:sales@feiyuepaper.com Company website: www.skyimagepaper.com Company Name: Fei Yue Paper Industrial Co.,LTD

博文

目前显示的是 七月, 2017的博文

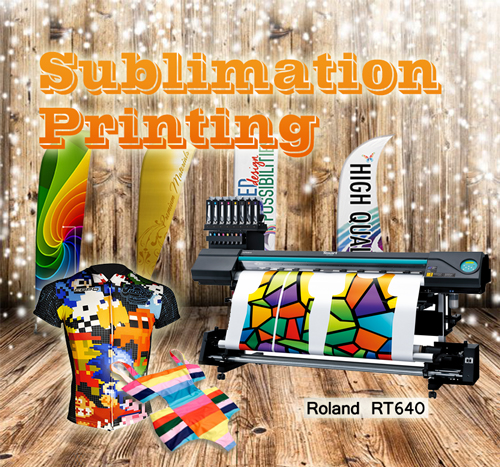

Popular dye sublimation printing solution for garments

- 获取链接

- 电子邮件

- 其他应用

Except Mimaki SB53, 54, Do you also know SB410 new generation sublimation ink?

- 获取链接

- 电子邮件

- 其他应用

Dye Sublimation Banners VS Vinyl Banners, Which is better?

- 获取链接

- 电子邮件

- 其他应用

What role does Sublimation Protection Tissue Paper play?

- 获取链接

- 电子邮件

- 其他应用

Tecnología de impresión por sublimación de colorantes para ropa deportiva

- 获取链接

- 电子邮件

- 其他应用

Different machines you need for dye sublimation printing

- 获取链接

- 电子邮件

- 其他应用

Epson range of dye sublimation solutions with sublimation printer

- 获取链接

- 电子邮件

- 其他应用

Stunning Cycling Jersey made by dye sublimation printing technology

- 获取链接

- 电子邮件

- 其他应用

Why choose dye sublimation printer for you textile business?

- 获取链接

- 电子邮件

- 其他应用

what benefits of Roland TrueVIS VG Series inkjet printer?

- 获取链接

- 电子邮件

- 其他应用

Amazing, How to sublimate whole t-shirt within ten minutes?

- 获取链接

- 电子邮件

- 其他应用