搜索此博客

Fei Yue Paper is Chinese professional sublimation transfer paper manufacturer, and our company is specialized in manufacturing sublimation transfer paper, sublimation dye ink, heat transfer machine for textile digital printing, If you are interested in our product, pls contact us freely. Whatsapp/Wechat:008618252072197 Email:sales@feiyuepaper.com Company website: www.skyimagepaper.com Company Name: Fei Yue Paper Industrial Co.,LTD

博文

目前显示的是 2017的博文

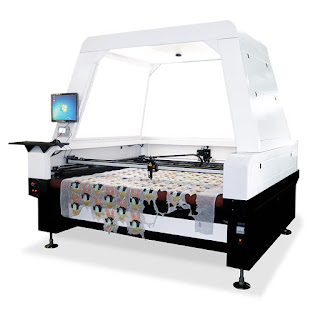

Tendencia de la moda de corte por láser en auge en el mundo de la moda

- 获取链接

- 电子邮件

- 其他应用

Various ink Chemistry suitable for various Fiber Types

- 获取链接

- 电子邮件

- 其他应用

Eco-solvent printing VS Solvent printing for Advertising

- 获取链接

- 电子邮件

- 其他应用

Mimaki JV150 series for Eco-solvent & Dye sublimation

- 获取链接

- 电子邮件

- 其他应用

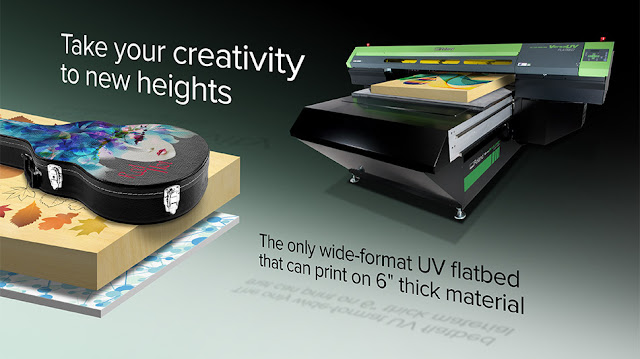

Wide application brought by advancement in digital print technology

- 获取链接

- 电子邮件

- 其他应用

Easy To Use, But Necessary To Research Before Purchase

- 获取链接

- 电子邮件

- 其他应用

Cómo utilizar la película de vinilo de transferencia de calor para patineta?

- 获取链接

- 电子邮件

- 其他应用

Which width of rotary heat transfer machine suitable for your sublimation printing business?

- 获取链接

- 电子邮件

- 其他应用

Fácil de usar, pero útil para investigar antes de la compra

- 获取链接

- 电子邮件

- 其他应用