Dye sublimation printing booming in textile industry

Nowadays, sublimation is applied in many products that we use every day. Its characteristics favor both the mass production and the personalization of products. It is a widely used process and with many applications in the textile industry. In this note we see basic concepts and applications and forms of production of textile sublimation.

The process of textile sublimation is a method that allows to stamp any type of design. From textile patterns or rapports to garment and accessory molds, sublimation has a wide field of application. It is a very versatile process since a sublimation printer works with inkjet technology. This allows a small number of meters to be printed at low costs compared to other technologies and with excellent quality.

But how is the process?

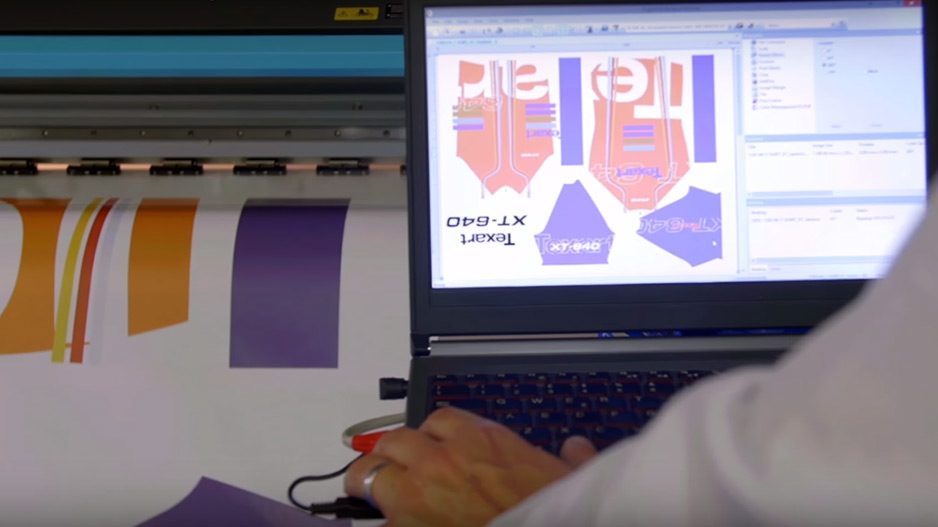

Textile sublimation consists of printing designs on sublimation paper in a sublimation printer with inks for this purpose. Once the printed paper is passed, the next process is stamped. For this, the paper and the fabric are subjected to a heating process. In this process, the temperature can reach 230 ° C, depending on the fabric. Through the heat that the fibers of the fabric open. In turn, the ink of the paper is sublimated, that is, it passes into the gaseous state and impregnates itself in the fabric. In this way the design is fixed and not removed any more. This process is constantly used in the textile world, whether in fashion and sport or in products for home decoration. This process is applied to fabrics with a high polyester content. This nowadays implies a huge field of application.

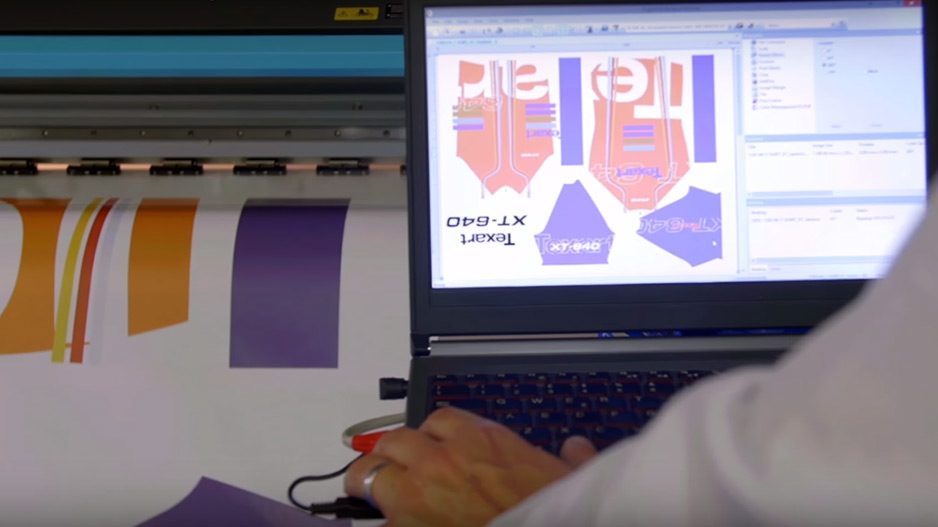

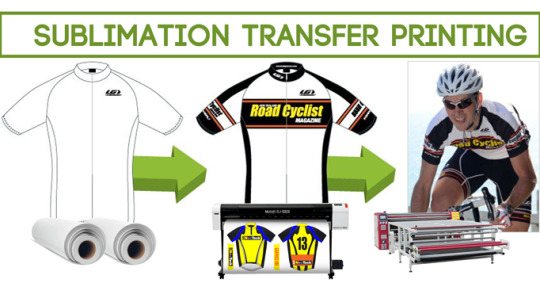

Now, within this process called textile sublimation there are different forms of production. Each one has its particularities, depending on the quantity and productivity needed. To sublimate made t-shirts and print logos or designs, small A4 format printers and small plates are also used. In the case of large or specific productions, where rapport is sought for textiles or designs throughout the fabric and lower production costs, large-format prints are used. For this process, textile industrial equipment is used, such as plotters, which work with papers that are 1.6 m wide for printing. In addition, the stamping is called textile calendering. The textile calendering can be carried out continuously, by roll or by garment.

More info:

Website: www.skyimagepaper.com

Company Name: Fei Yue Digital Technology Co.,LTD

E-mail: sales@feiyuepaper.com

Tel: 86-025-86628894

Whatsapp: +86 18252072197

Address: Central Road 323, Nanjing, Jiangsu, China

The process of textile sublimation is a method that allows to stamp any type of design. From textile patterns or rapports to garment and accessory molds, sublimation has a wide field of application. It is a very versatile process since a sublimation printer works with inkjet technology. This allows a small number of meters to be printed at low costs compared to other technologies and with excellent quality.

But how is the process?

Textile sublimation consists of printing designs on sublimation paper in a sublimation printer with inks for this purpose. Once the printed paper is passed, the next process is stamped. For this, the paper and the fabric are subjected to a heating process. In this process, the temperature can reach 230 ° C, depending on the fabric. Through the heat that the fibers of the fabric open. In turn, the ink of the paper is sublimated, that is, it passes into the gaseous state and impregnates itself in the fabric. In this way the design is fixed and not removed any more. This process is constantly used in the textile world, whether in fashion and sport or in products for home decoration. This process is applied to fabrics with a high polyester content. This nowadays implies a huge field of application.

Now, within this process called textile sublimation there are different forms of production. Each one has its particularities, depending on the quantity and productivity needed. To sublimate made t-shirts and print logos or designs, small A4 format printers and small plates are also used. In the case of large or specific productions, where rapport is sought for textiles or designs throughout the fabric and lower production costs, large-format prints are used. For this process, textile industrial equipment is used, such as plotters, which work with papers that are 1.6 m wide for printing. In addition, the stamping is called textile calendering. The textile calendering can be carried out continuously, by roll or by garment.

More info:

Website: www.skyimagepaper.com

Company Name: Fei Yue Digital Technology Co.,LTD

E-mail: sales@feiyuepaper.com

Tel: 86-025-86628894

Whatsapp: +86 18252072197

Address: Central Road 323, Nanjing, Jiangsu, China

评论

发表评论