搜索此博客

Fei Yue Paper is Chinese professional sublimation transfer paper manufacturer, and our company is specialized in manufacturing sublimation transfer paper, sublimation dye ink, heat transfer machine for textile digital printing, If you are interested in our product, pls contact us freely. Whatsapp/Wechat:008618252072197 Email:sales@feiyuepaper.com Company website: www.skyimagepaper.com Company Name: Fei Yue Paper Industrial Co.,LTD

博文

目前显示的是 五月, 2016的博文

2016 China international Textile printing Industrial Technology Expo

- 获取链接

- 电子邮件

- 其他应用

Jumbo roll size dye sublimation transfer paper for textile industry prin...

- 获取链接

- 电子邮件

- 其他应用

Jumbo roll dye sublimation transfer paper for MS JP fabric printing

- 获取链接

- 电子邮件

- 其他应用

Dye sublimation transfer paper for digital inkjet printer Roland

- 获取链接

- 电子邮件

- 其他应用

70inches (1 8m width) sublimation transfer paper Dgen ArtrixG5

- 获取链接

- 电子邮件

- 其他应用

Dye Sublimation jumbo roll transfer paper for high speed printer MS JP s...

- 获取链接

- 电子邮件

- 其他应用

80gsm~120gsm sublimation transfer paper for Mimaki digital printing

- 获取链接

- 电子邮件

- 其他应用

Sublimation transfer paper introduction & Its application

- 获取链接

- 电子邮件

- 其他应用

We will in CITPE 2016 | Fei Yue Paper Industrial Co.,LTD

- 获取链接

- 电子邮件

- 其他应用

Factory sublimation trasnfer paper production line showcasing for digita...

- 获取链接

- 电子邮件

- 其他应用

Distinctions between Dye sublimation printing and DTG digital printing

- 获取链接

- 电子邮件

- 其他应用

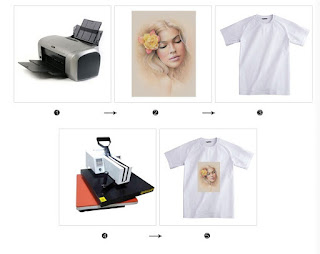

Sublimation printing on T shirt with A3,A4 transfer paper

- 获取链接

- 电子邮件

- 其他应用

Jumbo roll sublimation heat transfer paper for textile industry

- 获取链接

- 电子邮件

- 其他应用

Bleeding your images and why it is sometimes useful for sublimation

- 获取链接

- 电子邮件

- 其他应用

Digital textile printing brings new application opportunities to display print businesses

- 获取链接

- 电子邮件

- 其他应用

Basic 5 steps to heat transfer T-shirt with sublimation paper

- 获取链接

- 电子邮件

- 其他应用